Why Plumbing Vent Flashing Does Not Work with Roofing Cement

Depending on your roofing material and roof slope, there are different types of plumbing vent flashing that can be installed and NO - roofing cement is NOT one of them.

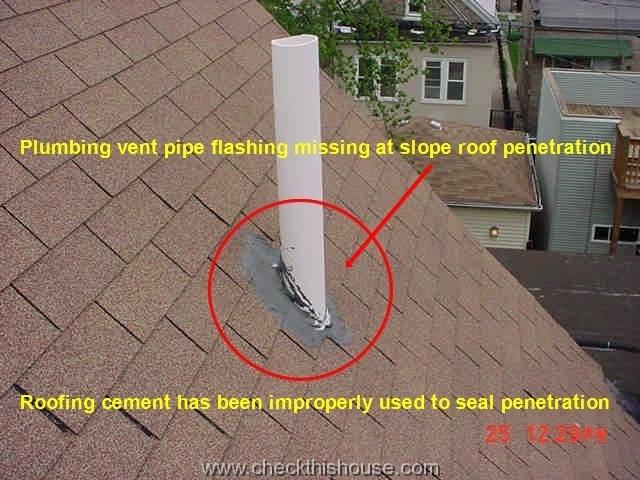

House plumbing vent flashing is required around the pipe at its roof surface penetration. Without it, or if improperly installed, rainwater or melting snow will seep around the vent and damage the roof decking material, sometimes making its way down to the wall/ceiling surfaces inside the property. As such, it’s recommended that you use an experienced plumber to avoid any regrets in the future.

How can an experienced plumber help you? First and foremost, an experienced plumber has the right tools and equipment to get any highly specialized plumbing work done fast and excellently. Hiring an inexperienced plumber could just cause more plumbing issues on your rooftop because of guesswork or improperly sealed vent flashing.

A plumber with local experience can help you plan the best design for your roofing systems plumbing vent flashing. In this way, you avoid the common problems associated with poorly installed vent flashing, such as leaks. Leaks could result in mold problems over time because the water can seep into your attic or ceiling, causing stagnation, mold growth, and proliferation. This problem could result in expensive mold remediation and structural repairs if neglected and health problems because of poor indoor air quality due to mold formation.

Make sure that you’re dealing with a qualified and experienced plumber. It pays off to ask your trusted friend or neighbor if they know a plumbing company offering this type of service. People who have experienced getting the same plumbing service are the best ones who can refer good plumbers in the area. You can also check some reviews online to know the best plumbing companies offering the service in your local area.

Depending on your roofing material and roof slope, there are different types of plumbing vent flashing that can be installed. Many people are tempted to use roofing cement because they seem reliable. Well, if you’ve been leaning towards that route, then it’s time to change your plans. Read on to learn more!

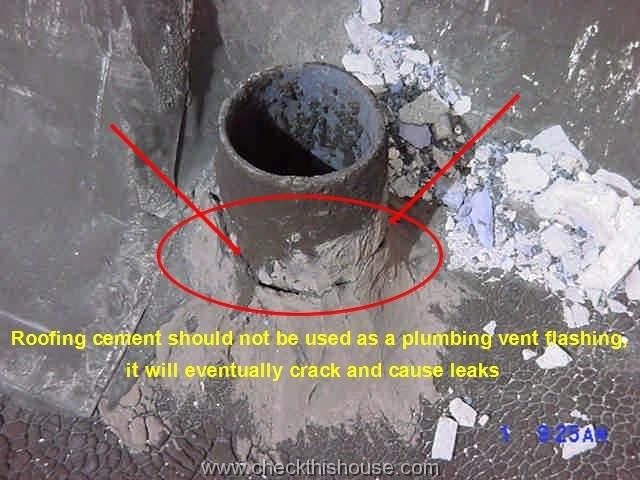

Question: Why roofing cement should not be used as a permanent plumbing vent flashing:

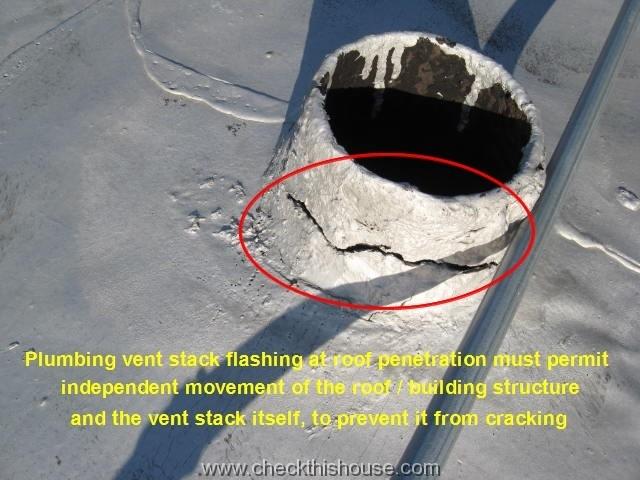

Answer 1: Because every roof structure contracts and expands independently from the plumbing vent stack. As such, the particles of the two materials (roofing material and plumbing vent stack) will not move uniformly. This will eventually lead to cracks along the vent stack.

Answer 2: Because every building settles differently from the plumbing vent stack. This could leave spaces between the vent stack and the roofing material, hence leading to leakages during the rainy season.

Both of the conditions (A1 & A2) will cause roofing cement applied around the plumbing vent stack to crack, separate from the pipe, and eventually leak water.

Plumbing vent flashing manufactured specifically for this application creates a waterproof/watertight seal around the roof-penetrating pipe without the use of any sealants. The most common types of materials used for this purpose are:

- neoprene rubber

- sheet metal with a neoprene rubber insert

- lead

There are also more sophisticated and expensive copper or galvanized steel plumbing vent flashing types assembled from two or more pieces. While serving the same purpose, they also add appeal to your house’s roof.

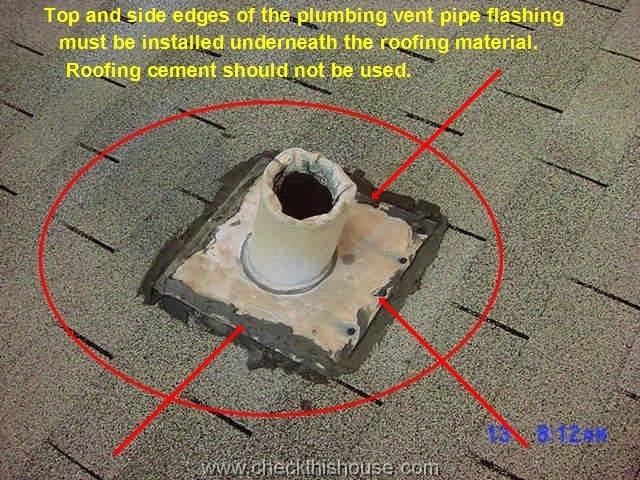

Neoprene rubber flashing and sheet metal with neoprene rubber types are very easy to install, but you have to keep in mind that water will penetrate it if you fail to do it right. The most common mistake is placing the flashing on top of the sloped roof surface material (shingles, rolled composition, metal, etc.) and applying roofing cement or caulking around it.

Top and side edges of the plumbing vent flashing apron (this section is mostly hidden under the roofing material) have to be inserted under the slope roof surface material with the bottom edge exposed.

Top and side edges of the plumbing vent flashing apron (this section is mostly hidden under the roofing material) have to be inserted under the slope roof surface material with the bottom edge exposed.

That open bottom edge prevents any possible condensation from the pipe sweating from being trapped under the roofing material, and can eventually cause roof decking damage or mold growth in the attic.

Any other installation is unprofessional and will most likely fail over time.

Of course, one can do some of these common plumbing vent issues by themselves, especially if it’s a renovation task. However, if you’re comfortable or skilled enough, it would be prudent to secure the services of an experienced plumber. There is no need of spending too much on materials only to come back for repairs after a few weeks.

Although neoprene rubber has a long life span, it might eventually crack along the seam with a plumbing vent pipe, and at that point, I would definitely recommend replacement.

Although neoprene rubber has a long life span, it might eventually crack along the seam with a plumbing vent pipe, and at that point, I would definitely recommend replacement.

If you’re able to pick a warm day for this procedure, it might be possible to slightly lift the top shingles (they will split/break if it’s cold and you will need to replace them) and replace the flashing without causing any damage.

You can use a hacksaw blade to remove nails holding down shingles located above the plumbing vent stack and the vent stack flashing itself. Just slide the blade underneath the surface and cut any nail that prevents flashing removal.

On some occasions, however, to properly install a new plumbing vent flashing, the roofing material needs to be removed from the vent surrounding area and be re-installed (especially on a multilayer roof).

Lead flashing has been used on plumbing vents for many decades, and because of its larger apron, it is still the choice of many roofers. It also slides down over the plumbing vent stack, but instead of the neoprene rubber that provided seal in the previous two types of flashing, a lead top section bends inside the vent pipe, and by overlapping it, prevents water penetration.

Plumbing vent pipe flashing made completely out of metal has a minimum of two pieces:

- Flashing/apron section, which also covers part of the vent pipe

- Counter-flashing secured to the top of the vent pipe and overlapping bottom section

Such design works like a telescopic antenna, allowing for structure movement independently from the plumbing vent stack; it definitely stands out from the crowd.

Plumbing vent pipe flashing installation on a flat or low slope roof also needs to provide for a building structure/roof framing independent movement. However, depending on the roof type, whether its metal, built-up roofs, modified bitumen roofs, single-ply (EPDM, EP, Hypalon, PVC, etc.), or membrane roofs, the installation procedure will vary.

Once again – the one thing that should not be used on any of those roofs as a plumbing vent pipe flashing is, and has always been, the roofing cement.

Once again – the one thing that should not be used on any of those roofs as a plumbing vent pipe flashing is, and has always been, the roofing cement.

Consider this – before you make another hole in your roof for that extra bathroom plumbing vent, check your attic. It might be possible to connect extra pipe to the house main plumbing vent stack without causing any roof damage. There is no right or wrong choice when it comes to such scenarios, but it’s important that you consider both the financial and structural side of things.

Comments are closed.