Water Heater Inspection Guidelines & Home Inspector Tips

Water supply and distribution line material requirements vary between jurisdictions. They might be copper, plastic, galvanized, or even lead in older buildings.

The following water heater inspection guide covers 3 types of the most popular water heater installations:

- Gas, natural draft, tank water heaters utilizing galvanized steel vent pipe

- Gas, power vent equipped, tank water heaters utilizing PVC vent pipe

- Electric water heaters

There might be some minor discrepancies between jurisdictions which will in most (probably not all) cases concern seismic areas water heater installations. I’ll cover it within this water heater inspection manual but I would highly recommend to obtain a water heater installation permit from your local building department (usually required) and verify plumbing code requirements in your particular area.

Water heater inspection general requirements, most apply to all 3 categories of water heaters

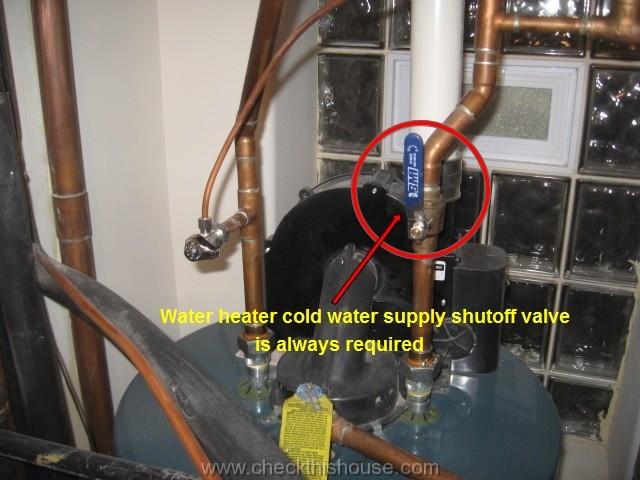

Water heater inspection – cold water supply line and a shutoff valve

There must be a water shutoff valve installed ONLY on a cold / inlet line of the water heater. This is required for the emergency and servicing purposes; so the water flow can be easily turned off in case of a leak or appliance servicing.

There must be a water shutoff valve installed ONLY on a cold / inlet line of the water heater. This is required for the emergency and servicing purposes; so the water flow can be easily turned off in case of a leak or appliance servicing.

The water shutoff valve must be installed at or near the water heater / only a full-bore valve type is permitted for this purpose.

![]()

![]() Water heater inspection – hot and cold water line connections

Water heater inspection – hot and cold water line connections

Water supply and distribution line material requirements vary between jurisdictions. They might be copper, plastic, galvanized, or even lead in older buildings.

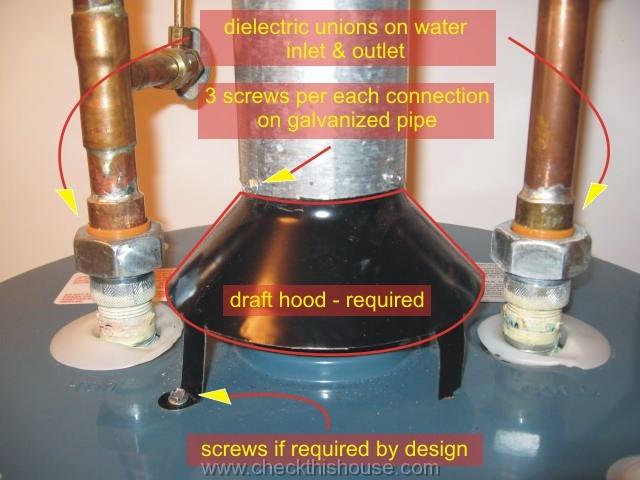

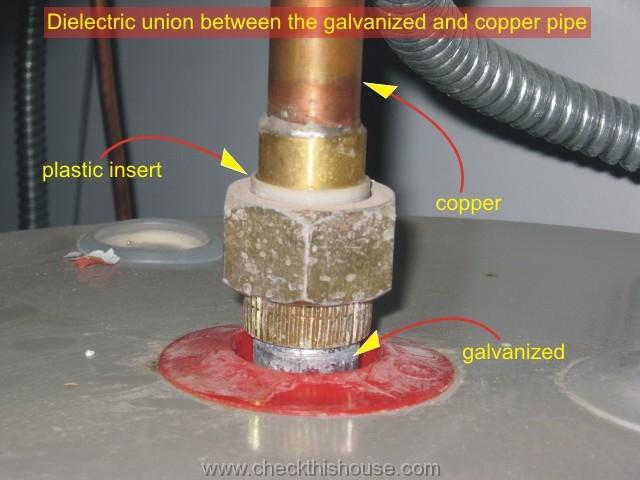

While performing water heater inspection check for union connectors; they are required within 12″ from the water heater’s inlet and outlet side. Their type will depend on the water pipe material in your home. Dielectric and brass unions are safe for all types of water pipe materials (required for copper water pipes) because they provide required separation for different metal types to prevent their corrosion. Galvanized unions can be used for galvanized and plastic water pipes only.

Some jurisdictions will require / some forbid final water pipe connection to the water heater to be flexible. Also, some will require heat traps / heat loops on those flexible lines. I believe that most of the new water heaters will have heat traps built in, if not, a curved flexible line directly above the appliance servs the same purpose; allows cold water to flow into the hot water heater’s tank and prevents hot water convection / mixing with cold water and flowing out of the tank when not in use.

Installed water heater lines union connectors should be checked for leaks during the water heater inspection.

Water heater inspection – hot and cold water pipes insulation

If you jurisdiction adopted UPC (Universal Plumbing Code), minimum R4 thermal resistance value insulation might be required on hot and cold water pipes withing 5′ from the water heater’s inlet and outlet.

Water heater inspection – hot water recirculating pipes

Some water heaters have a hot water recirculating loop installed, which guarantees instant hot water at the furthest faucet from the water heater. Unfortunately such installation wastes significant amounts of energy and all of the recirculating hot water pipes might require to be insulated.

Water heater inspection – insulation

Most newer water heaters include integral R12 or higher value insulation and do not require additional external blanket insulation installation. However, in case the water heater has a lesser value integral insulation or it has been installed in an unheated area, extra layer of insulation is recommended and might be required.

Water heater inspection – thermostat temperature settings

Water heater thermostat temperature setting is a serious safety issue but not a code requirement. The most recommended setting is under 125°F (48,88°C). But continuous exposure of a child’s skin can even at that temperature result in 2nd or 3rd degree burns.

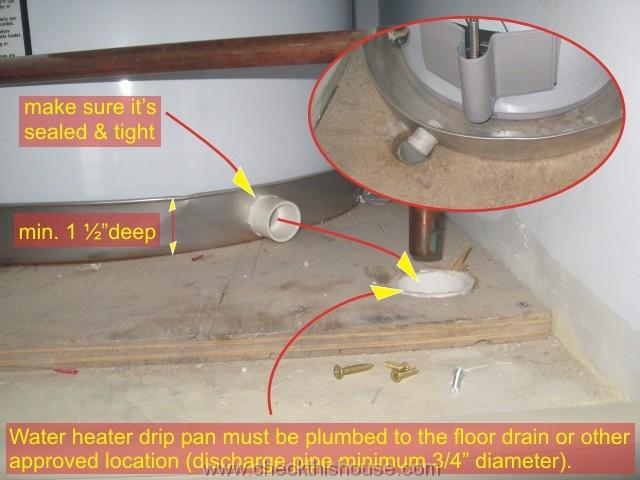

Water heater inspection – safety drip pan

Tank type water heater installations in areas where leakage could cause damage require protective watertight drip pan underneath. This requirement also applies to a cabinet / under the countertop installations.

Tank type water heater installations in areas where leakage could cause damage require protective watertight drip pan underneath. This requirement also applies to a cabinet / under the countertop installations.

- Protective pan must be made from an approved material; minimum 24 gauge galvanized steel or plastic

- Its minimum depth must be 1 1/2″

- It must have a minimum 3/4″ drain with a discharge pipe pitched for proper drainage into an approved location. Depending on your local adopted code this could be over a suitably located indirect wastereceptor or floor drain (it cannot be connected to a sewer line, vent pipe, etc.) or outdoors within 6″-24″ from the ground

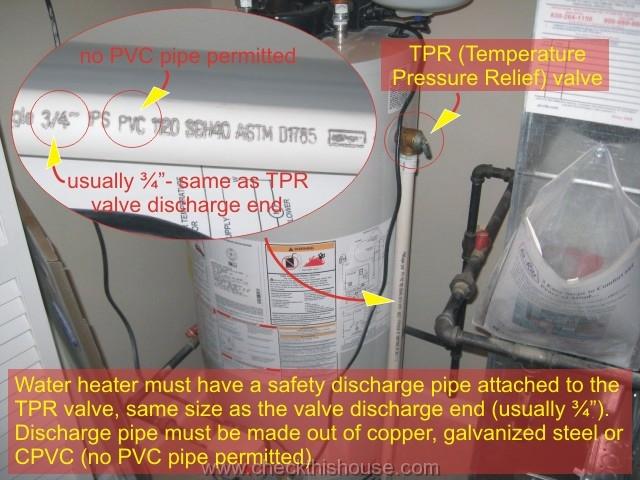

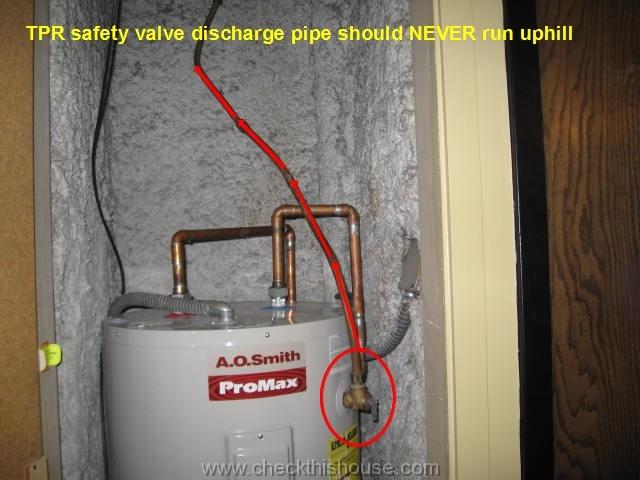

Water heater inspection – TPR valve (Temperature Pressure Relief valve)

All tank type water heaters must have a properly installed TPR valve! Every TPR valve must have a properly sized and made out of an approved material safety discharge pipe attached to it.

All tank type water heaters must have a properly installed TPR valve! Every TPR valve must have a properly sized and made out of an approved material safety discharge pipe attached to it.

Since this is an extremely important water heater inspection topic and serious safety issue, please follow this link to a dedicated article: water heater pressure relief valve

Water heater inspection – expansion tank

An expansion tank would be required if a check valve / back flow preventer has been installed on a cold water supply line creating what is referred to as closed water system.

Water heater inspection – combustion air requirements for any fossil fuel burning appliances

Sufficient amount of combustion air MUST be provided for the water heater to operate properly and to prevent incomplete combustion which might result in producing elevated levels of Carbon Monoxide gas.

Water heater inspection – gas connectors

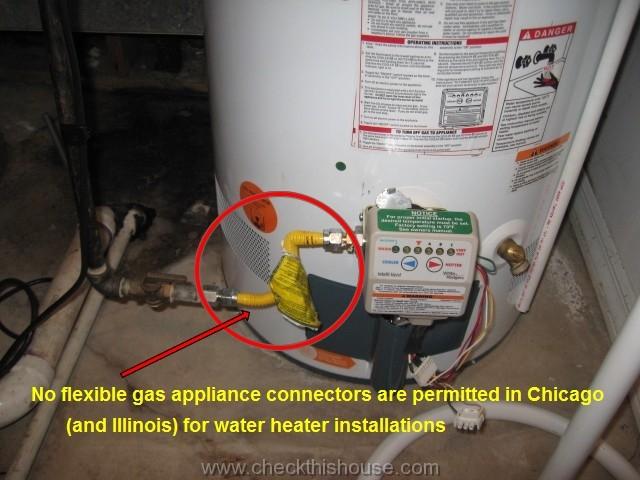

Some states (including Illinois) require heavy wall gas pipes or CSST (Corrugated Stainless Steel Tubing) as a water heater’s final gas connector. No appliance type (commonly used for gas ranges and clothes dryers) flexible connectors are permitted in Illinois.

Some states (including Illinois) require heavy wall gas pipes or CSST (Corrugated Stainless Steel Tubing) as a water heater’s final gas connector. No appliance type (commonly used for gas ranges and clothes dryers) flexible connectors are permitted in Illinois.

However, there are jurisdictions where flexible connectors might be recommended or required in water heater installations (seismic areas). Therefore, while performing water heater inspection, gas connector type should be verified with a local building department, and / or gas lines servicing utility company.

Common requirements for a gas flexible connector are that it cannot run through or be concealed inside any wall, floor, or other partition. Also, gas flexible connector should not come in contact with objects like metal wall studs, electrical wiring, copper or iron piping, paneling, sheet metal, etc.

Maximum length of a flexible water heater gas connector is 3 feet.

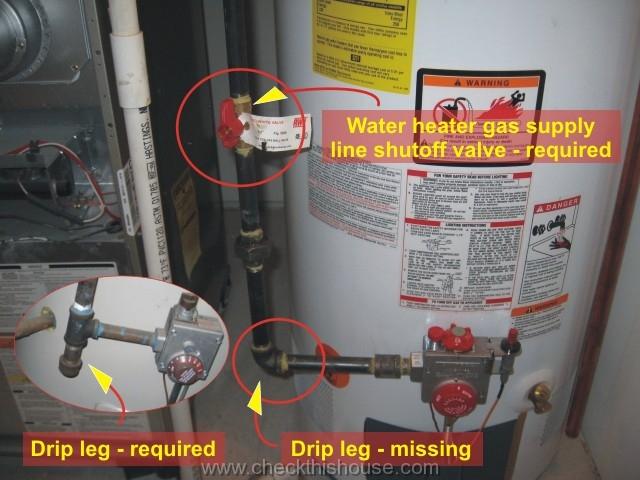

Water heater inspection – gas shutoff valve

Water heater must have a dedicated gas shutoff valve installed within 6 feet from the appliance, in the same room as the WH, and upstream of the union connector. Where a flexible connector is used, the valve must be installed upstream of the connector.

Water heater inspection – gas line union connector

A union or flanged connection is required between the gas shutoff valve and the water heater. Flexible connectors already include flanged connector so no extra union is needed when using one of those. This is to allow removal of the water heater or its controls without removal of the shutoff valve.

Water heater inspection – drip leg / sediment trap

Water heater gas supply line should have a sediment trap (also known as a drip leg) installed to collect moisture and prevent possibility of gas valve / thermostat contamination. It should be installed as close to the water heater’s gas valve / controller as practical at the time of equipment installation. Gas line’s drip leg can be in a form of a tee fitting with a capped nipple in the bottom or another device approved as an effective sediment trap. Again, this may not be required everywhere.

Garage water heater inspection

Follow this link – garage gas water heater – for explanation of such installation.

Water heater inspection – safety strapping

Tank type water heaters safety strapping might be mandatory in your area so please verify that with a local building department.

Based on the UPC (Uniform Plumbing Code) section 510.5, water heaters located in seismic zones 3&4 require strapping and / or anchoring to resist horizontal displacement caused by an earthquake. If you’re not sure about your seismic zone, use this US Seismic Zone Map (please let me know if the map is gone at that link) to determine it or call your local authorities.

The following general requirements stated in UPC might vary in your area: “Strapping shall be at points within the upper one-third (1/3) and lower one third (1/3) of its vertical dimensions. At the lower point, a minimum distance of four (4) inches (101.6 mm) shall be maintained above the controls with the strapping”

Follow this link for detailed California Guidelines for Earthquake Bracing of Residential Water Heaters

Natural draft, tank type water heater inspection

Water heater inspection – draft hood

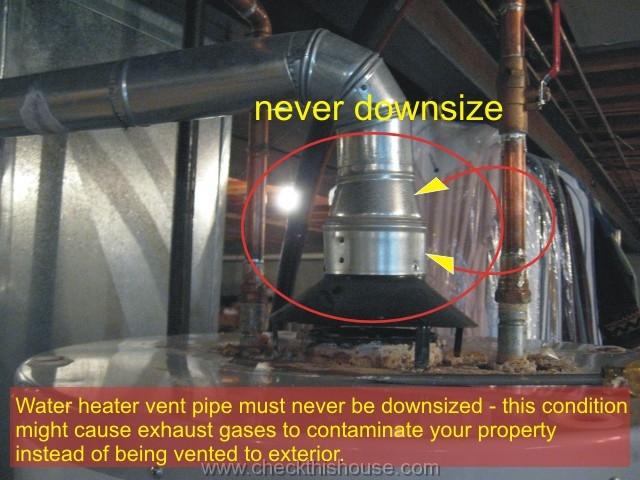

Water heater draft hood’s diameter depends on the size / BTU’s of the appliance. Residential size water heaters have usually 3″ or 4″ diameter draft hoods, some accept both sizes; the collar of the draft hood will have a profile that allows for different diameter vent pipes installation (picture).

A 3″ diameter draft hood should only have a 3″ diameter vent pipe directly attached to it. 4″ diameter vent pipe can be used as well but only with a reducing coupling.

In case the water heater and the draft hood have been designed to accept 4″ diameter vent pipe only, under no circumstances this pipe can be downsized!

In case the water heater and the draft hood have been designed to accept 4″ diameter vent pipe only, under no circumstances this pipe can be downsized!

New, 4″ diameter draft hood water heater installation in place of an old one that utilized 3″ diameter draft hood and a 3″ diameter galvanized vent pipe requires entirely new 4″ diameter vent pipe connector. No part of the old, smaller size water heater vent pipe can be re-used!

Water heater inspection – vent pipe vertical rise above draft hood

Although there is no UPC code that would mandate water heater’s vent connector having 12″ vertical rise above the draft hood, the Gama venting tables that are required for proper vent pipe / chimney calculations start with a 12″ minimum vent connector rise.

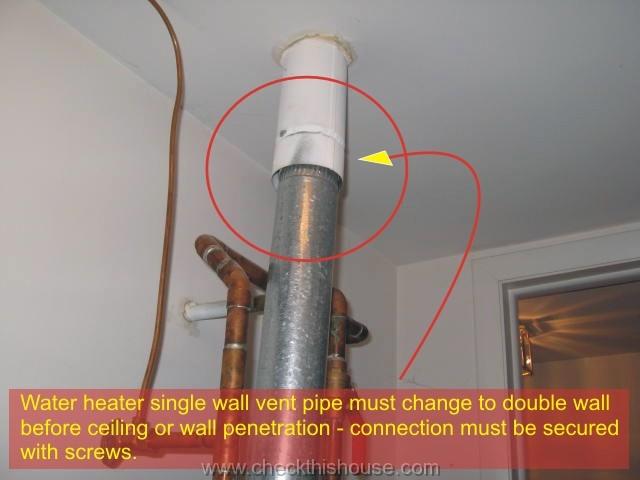

Water heater inspection – single wall vent pipe connections

All water heater single wall vent pipe connections must be secured with 3 sheet metal screws each (unless some other form of fastening has been approved in your jurisdiction) which includes draft hood connection. Using metallic duct tapes is generally not permitted on water heater vent pipes because it limits monitoring and prevents spotting corrosion and leakage signs, which should be investigated by a professional ASAP .

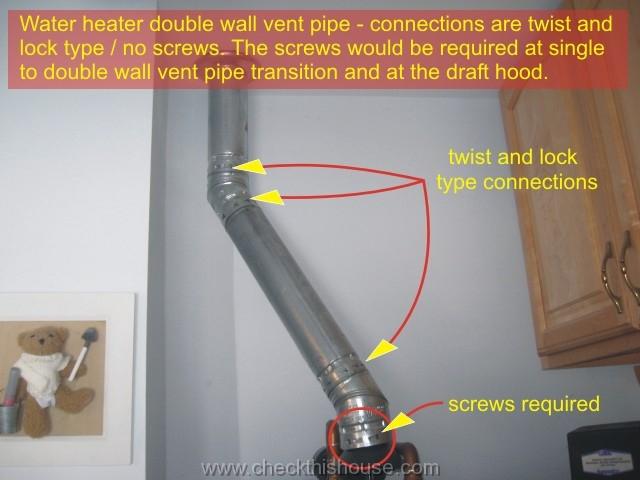

Water heater inspection – double wall / B-vent pipe connections

B-vent type water heater vent pipes require no screws on their joins because they utilize twist and lock connections. The only area that requires screws is the first joint with a single wall vent pipe or draft hood connection.

B-vent type water heater vent pipes require no screws on their joins because they utilize twist and lock connections. The only area that requires screws is the first joint with a single wall vent pipe or draft hood connection.

Water heater inspection – vent pipe clearance to combustible materials

- A single wall water heater vent pipe requires minimum of 6″ clearance to combustible materials

- Double wall / B-vent type connector requires 1″ clearance to combustible materials

Water heater inspection – single wall vent pipe locations

- Single wall vent pipe cannot pass through any walls, floor, ceilings

- Can be only installed in the same room as the water heater

- Single wall vent pipe may never be installed inside the wall / ceiling cavities

- Single wall vent pipe cannot be installed in an unheated or inaccessible area (attic, crawlspace)

Water heater inspection – vent pipe slope, support, and length

- Water heater vent pipe requires a minimum of 1/4″ rise per linear foot towards the chimney to maintain proper draft.

- The entire run of the vent connector must be sufficiently supported to prevent sagging and dipping.

- Maximum horizontal length of a single wall vent connector is 75% of the total vertical height

- Maximum horizontal length of a double wall / B-vent connector is 100% of the total vertical height

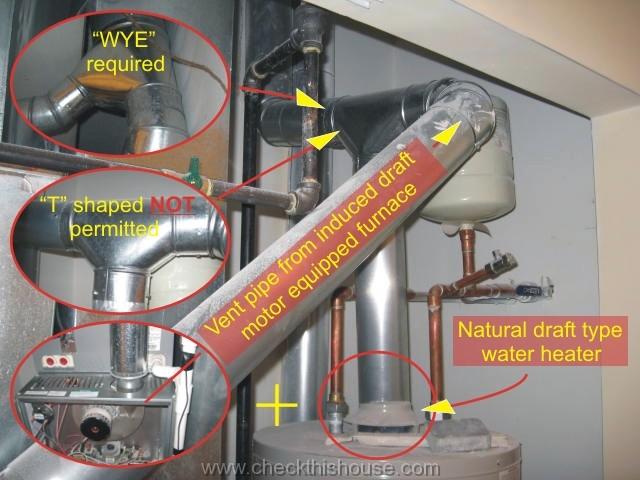

Water heater inspection – water heater and furnace vent pipe connection

Venting a furnace that utilizes induced draft motor and a natural draft water heater into a common vent requires “Y” shaped connection. This is required to prevent exhaust gases from the furnace from being pushed back into the house through the water heater’s vent pipe / draft hood.

Click – water heater venting – for an article dedicated to this subject.

Power vent, tank type water heater inspection

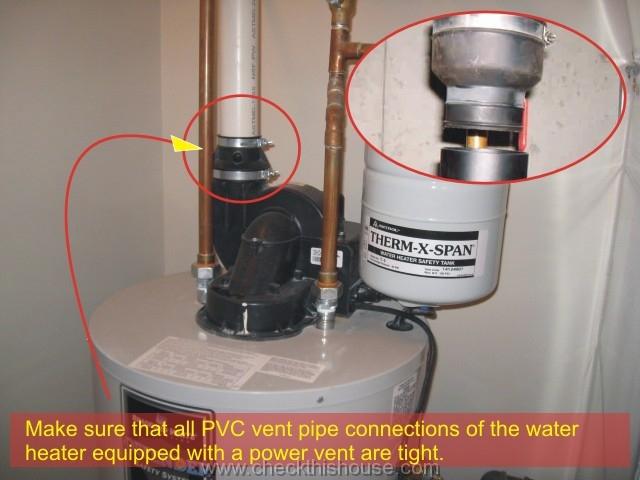

Water heater inspection – PVC vent pipe

Tank type water heaters utilizing power vent must have its PVC vent pipe joints sealed / glued using appropriate PVC cement that creates air tight joint. Using silicon for this purpose is not permitted.

The PVC vent pipe’s first connection to the power vent assembly collar is usually made with rubber sleeve / coupling and two clamps, which quiets vibration and minimizes its transfer onto the PVC vent pipe joints.

Water heater’s PVC vent pipe must be properly supported along its entire vertical and horizontal run to prevent sagging and dipping. Manufacturers span support recommendations vary between 3′-6′ with the first support / strap located immediately adjacent to the first 90° elbow. This might be further regulated by you local authorities.

The diameter and the minimum / maximum length of the water heater’s PVC vent pipe must be verified using the water heater’s installation manual. It usually depends on the appliance’s tank size, power vent motor, BTU’s, and the number of elbows along the entire run.

Click the following link – water heater PVC vent pipe – for additional material covering water heater’s PVC vent pipe. You need it to complete this power vent water heater inspection .

Tank type, electric water heater inspection

Water heater drip pan, TPR valve and discharge pipe requirements are the same as above.

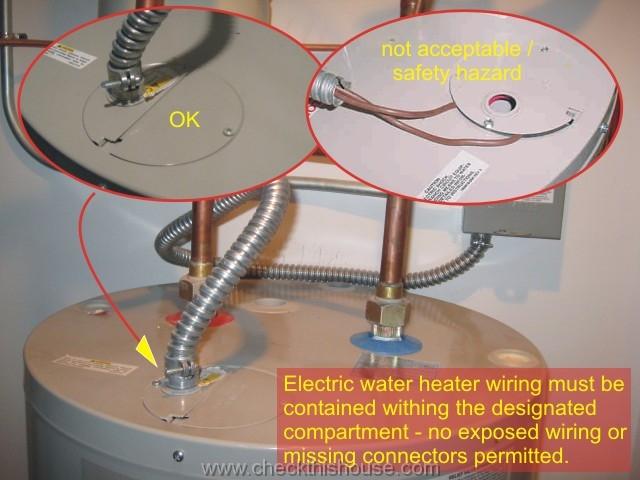

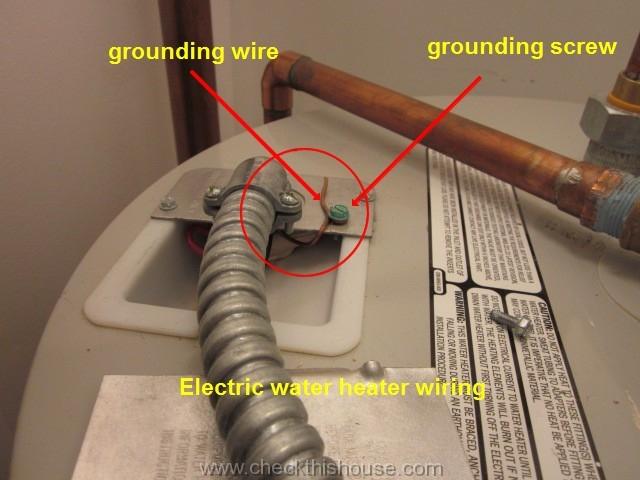

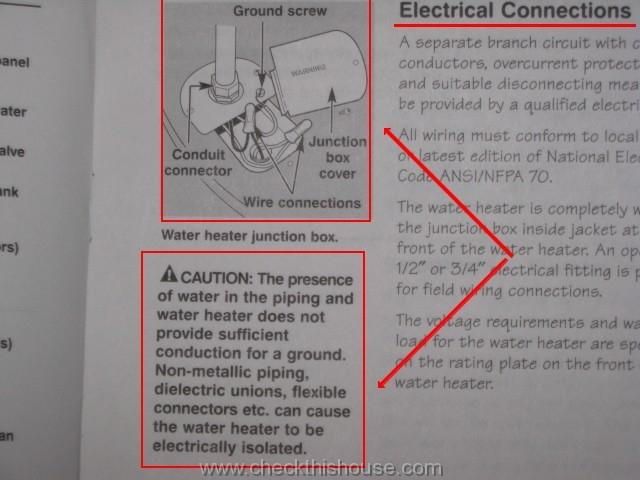

Water heater inspection – electrical connection

Electric water heater requires in-sight or lockable disconnect, 220V circuit breaker should be labeled accordingly.

Electrical conduit must be secured to the connection box with a listed type connector and wiring performed / concealed inside the compartment / protected with a cover.

Electrical conduit must not touch metal water pipes.

Electric water heater requires grounding – a ground terminal is usually located inside the connection box or in its vicinity.

Green color wire or green tape marked wire must be attached to the WH grounding terminal and to the electrical service ground terminal.

Water heater inspection – hot and cold water line connections

Water heater inspection – hot and cold water line connections

Comments are closed.